Benry Traverse Overview

Please pay attention to the following points when selecting a Benly Traverse model.

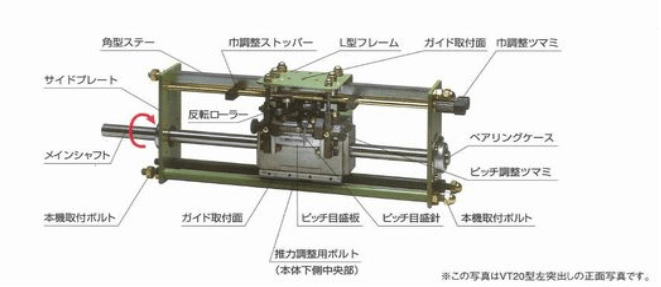

Benly traverse exterior

Benly Traverse parts names

*All models have the same mechanism except for some structures.

Model indication of Benley Traverse

Display example: For VT-1L20-50

| VT | 1 | L | 20 | 50 |

| Abbreviation for Benley Traverse | Spindle type 1 or 2 |

Shaft protrusion direction L or R |

Shaft diameter mm |

Frame outer width cm |

* Please refer to the standard dimension table page for the relationship between frame outer width (A dimension) and traverse width .

There are two types of spindles

| Type 1: Surface hardening type (standard specification) |

| Suitable when the stroke is short and there are many reciprocations. Click here if there are no specific instructions. |

| Type 2: Stainless steel type |

| When the stroke is long and the number of reciprocations is small. It is also suitable for use in areas where rust is likely to occur . |

Handling and precautions

Please pay attention to the following points when selecting a Benly Traverse model.

Direction of shaft rotation

- The main shaft can only rotate in a certain direction and cannot rotate in the opposite direction, so please select based on the direction in which the shaft extends.

Thrust force versus pitch and rotation speed

- Regarding thrust, the relationship between input rotation and pitch is that the slower the shaft rotation, the larger (stronger) the thrust, and the faster the shaft rotation, the smaller (weaker) it becomes. Also, the larger the pitch, the larger (stronger) the thrust, and the closer it is to zero, the smaller (weaker) it becomes. To use it in good condition, please set the pitch to about 50 to 70% of the maximum pitch.

Regarding the pitch, please see specification list 2

on the Benly Traverse specification page. *Pitch is the distance that the traverse body moves during one rotation of the main shaft of the Benly traverse.

About body installation

- Do not loosen the nut on the side plate side of the machine mounting bolt; fix it with another nut from the outside.

Regarding guide device installation

- Basically, one Benly Traverse is used for each guided material. Install guides such as pulleys as close to the traverse body as possible. Excessively long or heavy guides may cause malfunctions.